FDM printed components can be utilized for prototypes, industrial devices as well as components. The most typical material is PLA, which can be used to produce a wide variety of objects with fine details and also strong building and construction. Thermoplastics such as ABS and nylon are also generally utilized in industrial applications as a result of their high strength as well as ductility. These products can be made use of to construct get rid of internal honeycomb structures, decreasing weight as well as tiredness. Progressively, 3d sand printing devices are making it feasible to publish parts with a mix of various materials as well as additive technologies. These include Carbon Fiber-infused filaments, which can build get rid of similar toughness and also thermodynamic residential properties to steels, as well as electronic-filled pastes that can be utilized to make integrated circuits or batteries. A growing number of FDM-printed parts are currently being instilled with various other materials, including glass as well as ceramics.

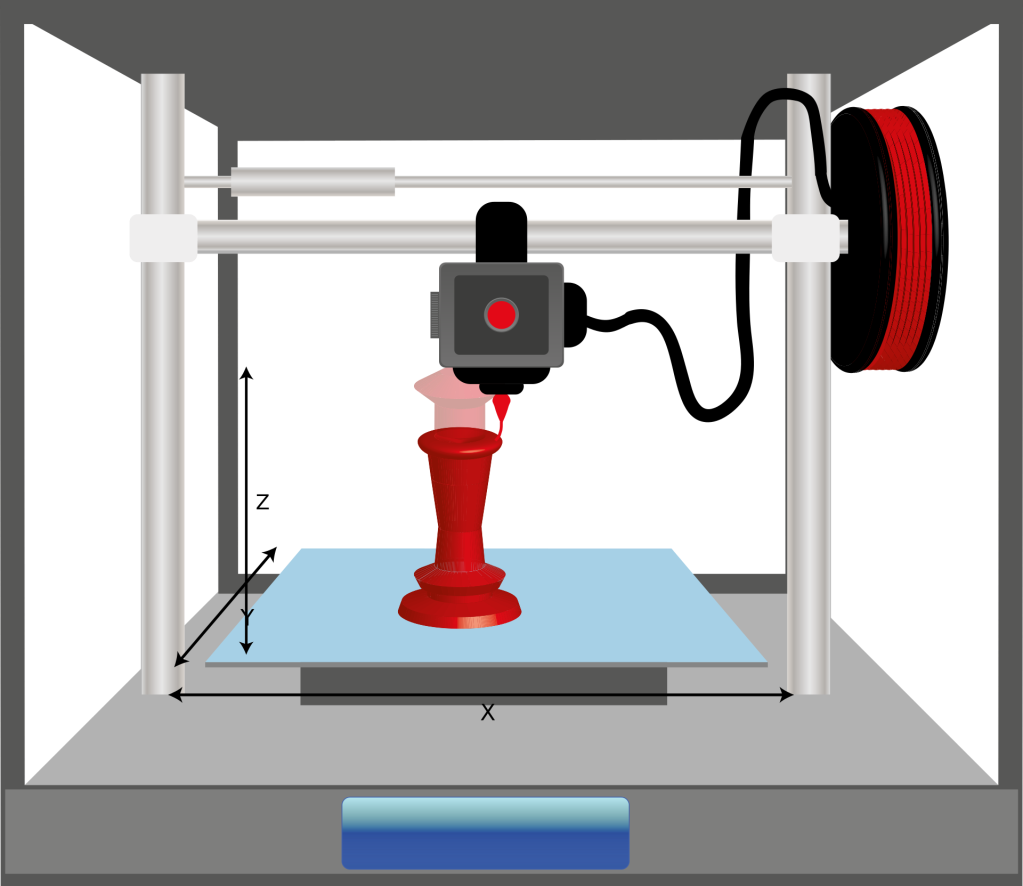

These products can be used to make individualized ornamental products, as well as even more robust medical tools. As an example, the Digital Foundry makes a series of carbon-fiber-infused FDM filaments that can build components as hard as light weight aluminum. Other developments check out the assimilation of electronic devices into FDM-printed components, utilizing metal-filled pastes to make incorporated circuits and also conductors. The FDM/ FFF procedure down payments layers of plastic by melting as well as extruding it layer-by-layer on the construct system, using a thin nozzle affixed to an extruder. This nozzle, which has a size of 1.75 or 2.85 mm, complies with guidelines provided by a 3D file to cut as well as deposit layers in accordance with the design’s layout.

Among the most typical troubles with the FDM/ FFF printing process is warping. This happens when a layer of the product cools at a slower or faster rate than other sections of the print. The distinction in cooling prices can lead to the underlying layer pulling upwards, triggering it to divide from the rest of the component. It is necessary to check the temperatures of your FDM/ FFF machine, consisting of the nozzle and also warm bed temperature settings. These settings can influence the high quality of your print, and need to be very carefully thought about to guarantee you obtain the best outcomes. Choosing the appropriate sand printing components for your task can make a significant distinction in the print quality of your FDM/ FFF project. Amongst one of the most common filaments are PLA (polylactic acid) and also abdominal (acrylonitrile butadiene styrene).

While both can be thawed and published, PLA is normally less complicated to publish and also can replicate details better than abdominal muscle. A large range of various other materials can be included right into the FDM/ FFF printing process, consisting of biodegradable as well as impact-resistant materials like polypropylene. These products can be used to produce resilient parts that are perfect for a selection of commercial as well as business applications, such as customer items, jigs and also fixtures, as well as also aerospace parts.

FDM/ FFF printing is a really versatile, economical and also easy to use 3D modern technology. It is specifically valuable for industrial prototyping as well as design of highly complicated parts, minimizing lead times as well as costs for both new as well as existing businesses. It is likewise beneficial for producing jigs as well as components in the automotive as well as aerospace sectors, in addition to for generating spare parts and custom items for classic automobiles. You can get more enlightened on this topic by reading here: https://en.wikipedia.org/wiki/3D_printing.

Leave a comment